Discover how to replace artificial red food colors with vibrant, stable, plant-based red alternatives. Learn practical tips for selecting, formulating, and optimizing natural reds.

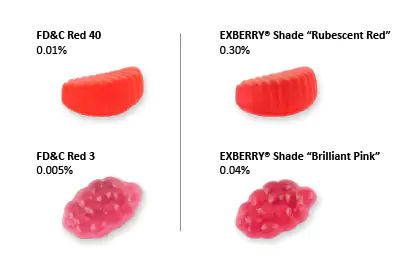

For decades, artificial red dyes like Red No. 3 (erythrosine) and Red No. 40 (allura red) have been the go-to for vibrant reds and pinks in confections. However, with the FDA’s recent decision to ban Red 3 from food and ingested drugs by January 2027, alongside California’s upcoming ban, manufacturers now face a pressing question: How can you replicate those iconic colors naturally—without compromising on stability, brightness, or shelf life?

Our application team loves tackling challenges like this because the payoff is worth it: bold, beautiful reds made from fruits and vegetables that resonate with today’s consumers. In this article, we’ll share what we’ve learned from hands-on testing in the lab and on the production floor, helping you confidently transition to plant-based colors while maintaining the vibrant look your customers expect.

Formulating for success: Making reds work for you

Replacing synthetic reds with natural alternatives is more than just a swap—it’s an exciting puzzle. Here’s how we approach common hurdles to help you create products that look stunning and perform flawlessly.

Step 1: Find your perfect red

Not all natural reds are created equal. Choosing the right source is key to achieving the ideal shade and performance for your product.

- Anthocyanin-based sources: Derived from colorful fruits and vegetables like radishes, red potatoes, and purple sweet potatoes, anthocyanins offer a range of red and pink hues. However, their color can be sensitive to pH: in acidic environments, they appear bright red or pink, while in alkaline conditions, they shift to purple or blue. These sources are versatile for a wide range of products, but the pH of the system plays a significant role in the final color.

- Beet-based sources: Beetroot adds rich pink and red hues but can be more sensitive to heat. We often recommend anthocyanins for heat-processed applications unless you’re looking for a red hue in a higher pH range (>5), such as cakes and muffins. For heat-sensitive beet-based color in baked goods (like red velvet cake), we work closely with you to optimize its performance, taking into account factors like processing time and temperature, formulation matrix, and the presence of ascorbic acid. We help determine the right dosage for your specific baked product to achieve the best results.

See the difference: Gummies made with vibrant, plant-based reds instead of synthetic Red 3 or Red 40. A perfect example of achieving clean-label brilliance while maintaining bold color appeal.

Step 2: Adjust & blend like a pro

Natural reds require a bit more finesse than artificial colors, but with the right approach, you can achieve stunning results:

- Small-batch testing: Ideally, we mimic your process as closely as possible, focusing on key parameters that impact color performance, such as pH, heating conditions, and base color. By testing different dosages and blends, we fine-tune the color to ensure it’s just right for your product.

- Blending for balance: Sometimes the best red solutions come from blending multiple colors. For example, adding orange to a maroon red can help brighten or warm the hue to a vibrant fire engine red. Blending also enables us to create custom hues while keeping costs in check.

- Planning for stability: For long shelf life, we often recommend slight overages or adjustments to account for heat-sensitive pigments, like beet, ensuring the color stays vibrant from the first bite to the last.

Our Binder Accelerated Stability Chamber speeds up color testing for food and beverages by up to 20X, offering rapid insights into dosage levels and raw material performance. This innovative tool helps us efficiently identify optimal color solutions for your products. Our team is here to guide you through this process—it’s what we do best!

Step 3: Fine-tune your process

Natural colors need a little extra care to perform their best. Here are a few tweaks we often recommend:

- Temperature tweaks: To preserve color integrity, minimize exposure to prolonged high heat during production. One effective strategy is adding colors later in the process to reduce heat exposure and maintain vibrant hues.

- pH adjustments: For pH-sensitive reds, like those from purple sweet potato, even a small decrease in pH can enhance brightness and improve stability, helping to maintain a vibrant, consistent color.

- Antioxidant support: Ingredients like ascorbic acid can enhance stability for heat- or light-sensitive pigments like beetroot.

We’re passionate about working side-by-side with our customers to fine-tune these small, impactful adjustments—together, we achieve the best possible outcome.

Tackling the toughest challenges with Red 3 replacements

Recreating the fluorescent hot pink of synthetic Red 3 is a challenge in natural color formulation. While plant-based alternatives like anthocyanins and beetroot can provide vibrant reds and pinks, they often don’t replicate Red 3’s exact intensity, especially in high-impact applications like brightly colored frostings or candies.

Anthocyanins are sensitive to pH, and their hue can shift based on the acidity or alkalinity of the product, making consistency a challenge. Beetroot, on the other hand, offers a rich red but is more heat-sensitive, limiting its use in high-temperature processes. These factors can result in a color that’s slightly different from the intense hue of synthetic Red 3 but still vibrant and visually appealing.

Despite these challenges, with the right formulation and testing, natural color alternatives can still deliver beautiful results that meet clean-label and regulatory standards. Our team works closely with you to navigate these complexities and achieve the best possible outcome, ensuring your products stay bold, stable, and on-trend.

Building trust through color stories

When you switch to plant-based colors, you’re not just making your products look great—you’re telling a story. Consumers care about what goes into their food, and sharing that your vibrant reds come from radishes, beets, or purple sweet potatoes can go a long way in building trust.

One of our favorite tips? Use your packaging to highlight these natural ingredients. It’s a simple, effective way to connect with your audience and reinforce your commitment to clean-label solutions.

Let’s solve this together

Whether you’re just starting to explore natural reds or ready to dive into formulation, we’re here to help.

- Request samples: Get natural red color samples tailored to your needs by reaching out through the form on this page.

- Schedule a consultation: Connect with our technical experts to tackle your unique challenges.

- Watch expert-led webinars: Click here for practical tips and insights on formulating with natural colors in beverages, confections, and baked goods.

Simply fill out the Contact Us form to the right to get started. Let’s work together to bring your natural color vision to life!